Press

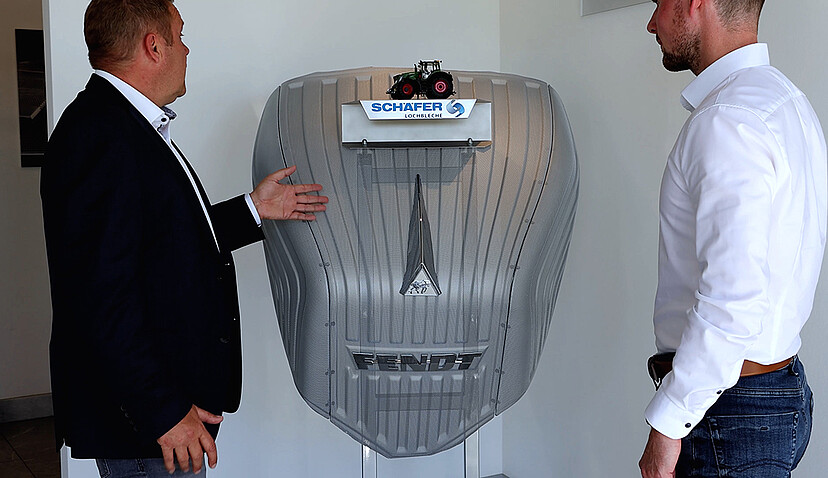

Neunkirchen, 19th March 2024. Perforated sheets are a proven construction and design element with a wide range of functions in the automotive and commercial vehicle industry. They take on very different forms, have to be installed in complex environments and do their job there for many years. Prominent examples include protective and ventilation grilles on engines, perforated body parts to optimise the weight of off-road vehicles and construction machinery, loading areas for vans and tow trucks and engine housings for tractors. In the development of engine protection grilles and radiator grilles, as well as in lightweight construction, SCHÄFER Perforated Metal recommends a hexagonal honeycomb structure – inspired by nature.

The perforated sheet itself is not complicated – it is simply a metal sheet with punched-out openings. When it comes to the finer details, however, precise and customised solutions are required in order to implement the advantages of perforated sheet metal in practice – including functionality, durability, stability and lightness.

SCHÄFER perforated sheets are used in particular for commercial vehicles, such as construction and agricultural machinery, which have to function in corrosive conditions with exposure to chemicals, moisture, dirt and mechanical influences. A prominent example is the Grenadier off-road vehicle from INEOS Automotive, which is manufactured at the former Mercedes-Benz plant in Hambach.

Nine individual protective and ventilation grilles are visibly located at the front of the vehicle and are optimised for air flow to cool the engine. In addition, they provide permanent protection of the engine against the mechanical impacts that are common in everyday off-road use. The grilles are manufactured in Neunkirchen in North Rhine-Westphalia and delivered ready for installation.

Each hole type has specific areas of application and offers individual advantages. A diamond-shaped perforation allows a free cross-section of just under 75 per cent. In other words: One square metre of perforated sheet then consists of 25 per cent metal and 75 per cent open surface, which explains the enormous weight reduction. With the hexagonal perforation Hv 6.0–6.7, the free cross-section and the weight reduction likewise can be increased to over 80 per cent. This optimises air permeability, increases rigidity and provides protection against mechanical impact from objects with a diameter greater than 6 mm.

"The original plan for the INEOS Grenadier was a diamond-shaped perforation for the engine guard. Of course, we could have supplied this. During the design-in process, however, we worked with the engineers and designers at INEOS to identify the advantages of hexagonal perforation for this application. The increase in air flow achieved of a good eight per cent has a measurable effect on engine cooling. As a result, the engine works more efficiently and is just as well protected against stone chipping as with the diamond perforation," explains Torsten Schoew, automotive expert in the field of engine protection and cooling at SCHÄFER Perforated Metal.

The challenge in producing the hole pattern Hv 6.0–6.7 is the ratio of hole size (6 mm), material thickness (1.0 mm) and web width (0.7 mm). The 0.7 mm thin webbing must not tear during production and must be able to withstand external influences even in harsh environments. This requires expertise and precise punching tools, which SCHÄFER Perforated Metal manufactures in its in-house tool shop.

In the production of perforated sheets, metal punches are pressed into the smooth sheet surface by machine, creating the specific hole patterns. Process-related burrs occur on the punch exit sides on the underside of the sheet. At SCHÄFER Perforated Metal, these are deburred as standard in an additional work step during production. Only then is further processing using chemical or electrochemical processes recommended for permanent corrosion or oxidation protection of the perforated sheets.

High-quality perforated sheets are a prerequisite for durable solutions. The base material comes from the SCHÄFER WERKE Group's EMW Steel Service Centre, one of the largest plant-independent steel service centres in Europe. EMW has an average of over 300,000 tonnes of thin sheet (0.25 to 16 millimetres) readily available in almost all marketable grades. The perforated sheets business area also benefits from this.

Among many other steel grades, Magnelis® flat steels from ArcelorMittal are processed, which are also available from EMW. Magnelis® flat steels are characterised by self-regeneration at cut edges and are therefore particularly resistant to corrosion. The perforated sheets, which are manufactured with a wide variety of hole patterns, can be finished in the standard RAL colours at the factory. The long-term corrosion resistance has been tested and certified by independent third parties using a salt spray test.

The company's product range includes over 400 immediately available hole patterns, which are designed as round, square, diamond, slotted or hexagonal perforations. Steel, stainless steel, aluminium, copper, zinc, brass and plastic are used for processing. An in-house design department with application specialists is responsible for developing customised patterns and optimisation for highly complex applications. This means that almost all conceivable applications and design requirements can be realised.